Forklift Design & Classifications

Most of us have a good idea of what a forklift looks like—but there are actually seven specific classifications of forklifts or industrial trucks. The classifications are established by the Occupational Safety and Health Administration (OSHA), and include the following types of forklifts:

Class I: Electric Motor Rider Trucks

These electric-powered forklifts are ideal for loading and unloading tractor-trailers, handling pallets, and a number of other applications in industries ranging from food storage and retail to factory and general warehousing.

Because an electric battery powers them, Class I forklifts are much quieter and create no emissions, making them a popular choice for indoor applications. Batteries on Class I forklifts also function as part of the counterweight to help maintain lifting capacity. The models in Class I include:

Class II: Electric Narrow Aisle Trucks

As the name suggests, Class II forklifts are designed with maneuverability that allows them to operate in tight spaces and narrow aisles. This class of forklifts is perfect for picking and putting away inventory, and these trucks provide users the ability to increase racking space without expanding their current warehouse. Class II models include:

Class III: Electric Motor Hand Trucks

This class of equipment comes in both rider and walk-behind (“walkie”) models, perfect for unloading deliveries and moving loads to a staging area where they can be handled by other types of forklifts. Class III forklifts include:

Class IV: Internal Combustion Engine Truck (Solid/Cushion Tires)

This class of sit-down forklifts is designed for indoor use. Class IV Forklifts are powered by internal combustion (IC) engines that run on diesel fuel, LP gas, gasoline, or compressed natural gas. Their solid, cushioned tires provide a smooth ride on indoor surfaces and they’re puncture-proof since they are not air-filled. Toyota offers seven Class IV models, ranging in lift capacity from 3,000 to 100,000 pounds.

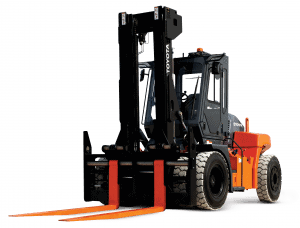

Class V: Internal Combustion Engine Trucks (Pneumatic Tires)

Forklifts in this class are similar to those in Class IV but are designed primarily for outdoor use. These forklifts are highly durable and are ideal for lumberyards, construction sites, and other outdoor applications. Toyota offers eight forklift models in Class V, ranging in lift capacity from 3,000 to 125,000 pounds.

Class VI: Electric and Internal Combustion Engine Tractors

These machines are most commonly used for towing loads rather than lifting. Trucks in this class are ideal for use at airports but are also commonly used in assembly line areas. Tractor models include:

Class VII: Rough Terrain Forklift Trucks

Trucks in this class feature large, tractor-style tires and are powered almost exclusively by diesel engines for outdoor use in rugged terrain. Class VII trucks are most commonly used at lumberyards or construction sites to lift building materials to elevated work sites.

These classifications give some general differences between forklifts, such as different types of tires, power sources, and terrain. Within each classification, there are also options for load-bearing, maneuverability, and control.

How to Choose Between IC (gas-powered) or Electric Forklifts:

Deciding whether an internal combustion forklift or electric forklift is appropriate for your application can seem like a daunting task. Here are some high-level considerations that you might take into account when choosing between a gas-powered and electric-powered forklift:

ELECTRIC FORKLIFT BENEFITS

- Typically less maintenance than I/C forklifts

- Quieter with little emission sounds

- No fuel-storage requirements

- Requires a charging station

- No tailpipe emissions

- Lifespan depends on the application, use, and maintenance

- A better option for smaller, confined areas

INTERNAL COMBUSTION FORKLIFT BENEFITS

- Operate on gasoline, diesel, compressed natural gas, or liquid propane gas

- Primarily used outdoors, but can be used in moderation in some indoor applications

- Can operate in various conditions

- No batteries to recharge

- Toyota’s IC Forklift line can lift over 51,000 lbs.

- Lifespan depends on the application, use, and maintenance

- Noise emissions meet or exceed ANSI B56.1 standards

Forklifts can be fitted with pneumatic tires, made of durable rubber that can go outdoors. These tires can be similar to the tires on your car, or solid tires, called cushion tires in the industry, which are made of solid rubber, typically used on forklifts that will be used indoors on hard and flat surfaces.

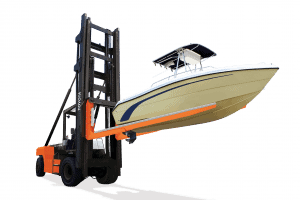

Forklifts can be outfitted with different attachments, such as carrying barrels or rolls of paper instead of lifting pallets. Each type of forklift class is designed for certain types of loads and specific working conditions.

Don’t know which forklift fuel type is best for your business? Contact us and we can help!