We understand the importance of maintaining a highly productive operation all while instilling a culture of safety in your facility. You need to be able to move products faster while keeping your operators comfortable and secure. Toyota offers the latest and greatest technologies to help you keep your eye on the prize and push your operation forward. Toyota engineers and developers have designed a robust family of features and options that work together to passively or actively assist certain operations in regard to operability, productivity, or situational awareness. Toyota Assist is here to help you carry the load.

Load Handling

Toyota forklifts don’t just meet the bare minimum. They go beyond what is expected and put the operator at the forefront of our work. That’s why load-handling controls are designed to help each operator efficiently and safely retrieve and move products throughout their facility.

System of Active Stability

At the core of the many safety elements built into Toyota Forklifts is the proprietary System of Active Stability™ (SAS). This game-changing and industry-leading forklift technology minimizes the likelihood of tip-over, reducing the risk for operators and those around them. When the system detects a situation that could lead to instability, it instantly engages the swing lock cylinder to stabilize the rear axle – changing the forklift’s stability footprint from a triangular to a rectangular shape.

Putting You In Control

While some operators are content with using the same bells and whistles they’ve grown accustomed to over the years, there are many new technologies available that may make their lives easier, as well as make the tasks more comfortable. Toyota has engineered a variety of ergonomic features designed to put operators in control – so they can get the job done efficiently and comfortably.

EZ Fingertip Controls™

EZ Fingertip Controls put productivity at the forefront by placing all hydraulic controls in an ergonomic pattern that can be reached with minimal hand movement. Thanks to an included horn button and forward/reverse directional switch, operators can conveniently maintain one hand on the steering wheel while allowing the other hand to control all necessary functions outside of braking and travel. This intuitive design helps with operator comfort, and controls can be customized to manipulate up to five hydraulic functions, including clamp release interlock.

While some operators are content with using the same bells and whistles they’ve grown accustomed to over the years, there are many new technologies available that may make their lives easier, as well as make the tasks more comfortable. Toyota has engineered a variety of ergonomic features designed to put operators in control – so they can get the job done efficiently and comfortably.

Toyota’s EZ Control Joystick®

Toyota’s EZ Control Joystick® offers a progressive, ergonomic approach to material handling by putting all hydraulic controls, horn button, and travel directions in a singular handle. An intuitive axis-based pivot combined with strategic button placement and smooth operation puts operators comfortably in control of the most precise material handling challenges. The ergonomic design helps reduce operator fatigue and allows for multiple functions at once such as lift and tilt.

Heightened Awareness

While moving products from point A to point B is important, operational awareness is key to ensuring a culture of safety in your facility. Toyota has engineered state-of-the-art stereoscopic vision technologies that can assist operators in identifying pedestrians or objects during a shift.

SEnS Smart Environment Sensor®

The SEnS Smart Environment Sensor® (SEnS) pedestrian detection system – designed and engineered by Toyota – uses stereoscopic vision technology to assist operators by differentiating between pedestrians and objects, and providing visual and audible alerts within the detection zone. Along with SEnS, by adding a 360 camera system, you now have the ability to have a bird’s eye view of your forklift to assist in navigating tight environments. SEnS is available as an add-on kit that can be retrofitted for select existing Toyota forklift models, as well as new models.

SEnS+ Smart Environment Sensor Plus

In addition to SEnS, Toyota has developed SEnS+ Smart Environment Sensor Plus™ which not only detects pedestrians or objects, behind the forklift but it limits the movement of the forklift by automatically slowing down the equipment when pedestrians and/or objects are detected. With dynamic zoning, SEnS+ adjusts the range of detection based on the speed of the forklift. If the forklift is moving faster, the zone is expanded to account for potential upcoming obstacles further away, up to 32 feet. When the truck is moving slower, the zone is decreased to prevent unnecessary distractions for obstacles that are not within range. And lastly, as the forklift is traveling in reverse and turning, the zone automatically tracks the steering direction. SEnS+ is available on select Toyota Forklift models.

Vertical Versatility

We understand the importance of having the right material handling equipment to get the job done. Our solutions are loaded with features to tackle your unique tasks and keep your operation moving forward.

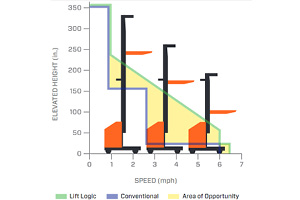

Toyota’s Lift Logic

Toyota’s Lift Logic option is a productivity-enhancing solution for the most demanding, high-throughput, order-picking applications. Lift Logic continuously monitors the height of the forks, and adjusts speed accordingly. This allows for the maximum speed appropriate for any height in its range.

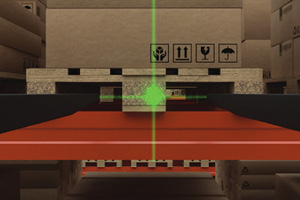

Toyota’s Acu-Laser

Toyota’s Acu-Laser automatically projects a red or green laser line onto the pallet, allowing precise pallet placement and showing the operator the fork’s position.

Auto Height Select

With Auto Height Select, the operator can select up to 25 programmable present lift heights, using the reach and retract control handles buttons. When the operator lifts, the carriage stops automatically near the selected height. The operator then finely adjusts the height manually to place the load in the rack location.

Features for All Heights

Carriage Mounted Camera

The Carriage-Mounted Camera provides operators with an additional visual aid for positioning forks at high heights.

360o Operating Camera

The 360o Operating Camera gives you the ability to view multiple areas around the forklift to assist in tight environments.

Ground-level Monitoring Kit

The Ground Level Monitoring Kit with DVR helps monitor and record activity around heavy-duty forklifts.

Object Detection Radar

Object Detection Radar uses a high-resolution radar sensor that is mounted to the back of the counterweight to detect both moving and stationary objects behind the forklift.

Load Weight Sensing

Load Weight Sensing utilizes hydraulic pressure sensors along with a display to show the operator the approximate weight of the load they’re carrying.

Twistlock Snapshot Camera System

The Twistlock Snapshot Camera System captures images of containers and spreader engagement before and after each container is handled.

Compartment Sensing System

The Compartment Sensing System on the Stand Up Rider uses multiple light beam sensors that are embedded in the rear operator compartment. When the sensors are blocked, a tone will sound and a message will appear on the operator display screen, and the truck will decelerate to a stop if traveling.

Product features described here may be optional and may not be available across all Toyota products. Please contact the experienced team at Summit ToyotaLift for specifications. Details of specifications and equipment are based on information available at the time of printing and may change without notice.